The spring eye bearing is

a development of Jörn GmbH.

Leaf spring bearings are the connections between a leaf

spring or the handlebar of an air spring and the vehicle frame. Everything goes

through here. They are used in the spring frame and in the open spring eye.

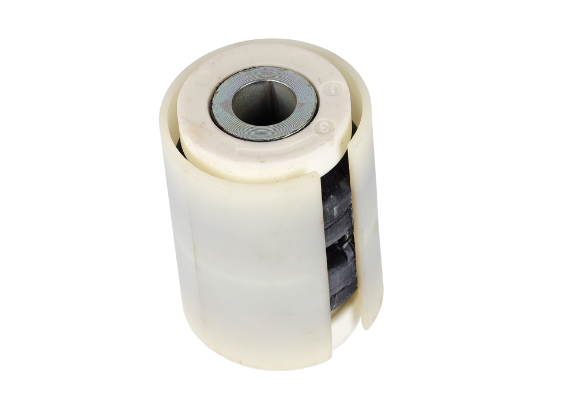

Depending on the requirements, they consist of a rubber-steel or rubber-plastic

combination and have one or more rubber layers.

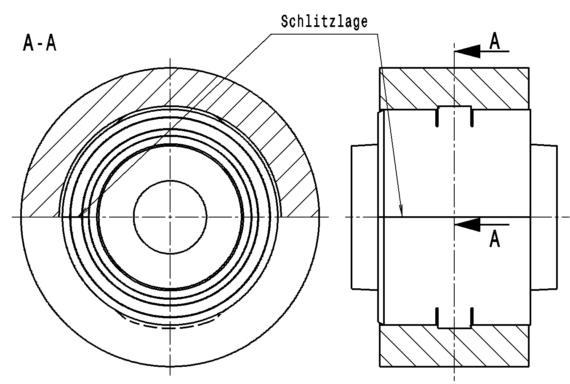

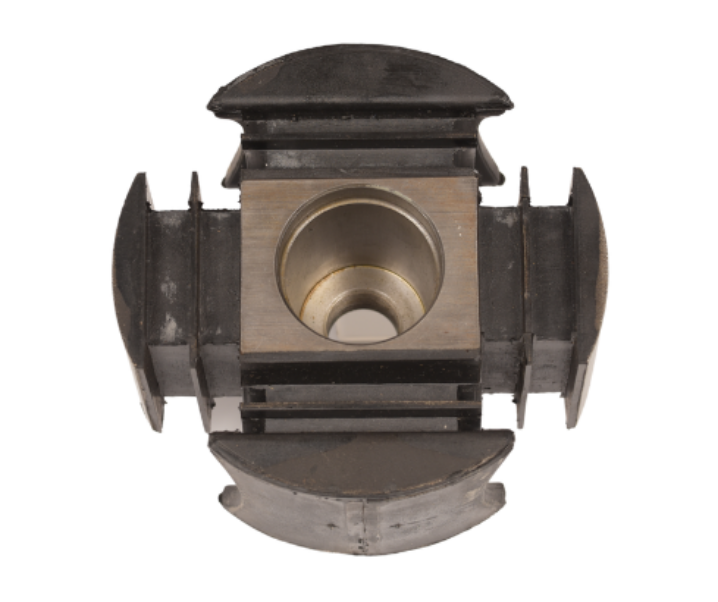

The leaf spring eye bearing is a special form of the slit

bushing. It consists of a thin-walled inner tube with a rubber film on the

inside and an inserted steel tube.

In the rare case of large twists, the inner tube slips through the slit bushing and thus offers overload protection. Pressed back-up rings on the steel tube of the spring eye bearing significantly increase the axial stiffness of the bushing. They improve the lateral control of the vehicle, limit the radial spring travel and the gimbal deflection. Depending on the load, the back-up rings can be made of plastic, steel or high-strength steel. With a vulcanizing part, Jörn offers a whole modular system for different applications.

The leaf spring eye bearing compensates for

the typical effect of elastomers of flow and setting and convinces with a long

service life, especially when used in the open spring eye. The background: When

pressed in, the spring eye is elastically expanded. If the elastomer settles,

the pressure on the eye decreases and the diameter of the eye decreases. As a

result, the slot bushing is retensioned until a new tension equilibrium is

established between the elastically deformed spring eye and the preloaded bushing.

The axial pressing force in plastic eyes is

significantly lower than in the steel eye. For use in leaf springs made of

fiber-reinforced plastic, we therefore recommend spring eye bearings with

integrated emigration protection.

development process of rubber metal parts

Mr. Reinke presents the new format: SECRETS OF JÖRN GMBH

Here is the first part about the development process of rubber-metal parts at

Jörn GmbH. From simulation to FEM and first samples, to the release of serial

parts.

Among other things, Mr. Reinke also discusses the special

characteristics and pitfalls of rubber materials and their effect on

development and testing. Enjoy the video and look forward to more parts about

our secrets. Your Jörn Team