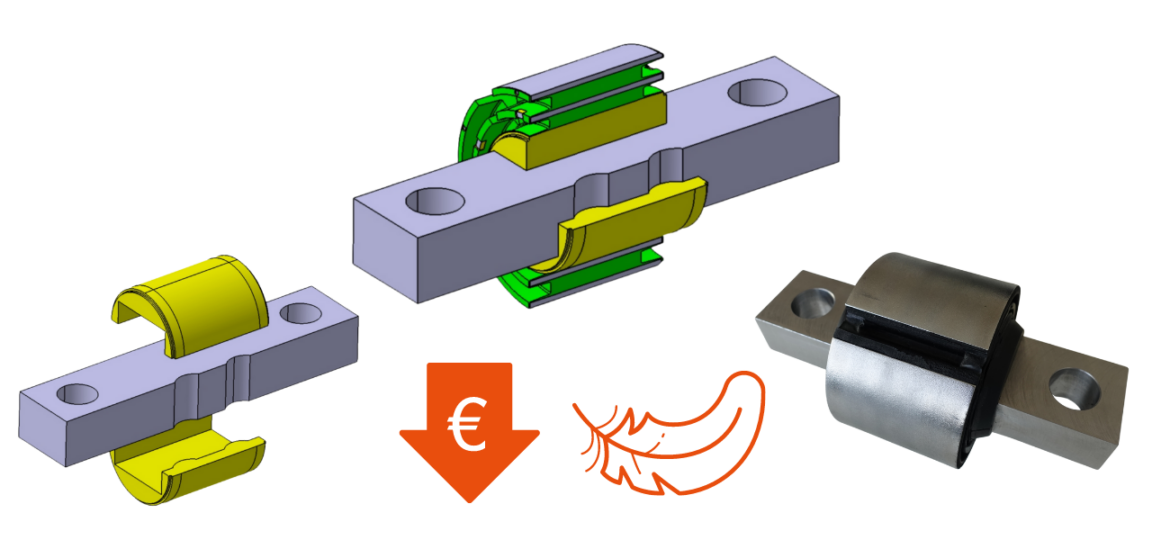

Lightweight Joints

Sustainable, innovative and up to a third lighter

33%

lighter with the same performance

We have taken the tried-and-tested, millionfold used slit bushings and ball

joints, both inventions of the company Jörn, further and developed lightweight

construction variants.

Why?

Well, the reasons are manifold. The most important thing: lightweight construction is sustainable, because every kilogram that does not have to be moved does not require any energy. Lightweight construction is a contribution to sustainability and resource conservation.

Yes, it’s not a new hydrogen engine, but when you consider how many slitted bushings and ball joints are installed in commercial vehicle chassis all over the world, you get a lot of mass.

An example: A serial part, of which we deliver 100,000 pieces per year to our customer, becomes 1 kg lighter. These are savings of 100 tons of steel that are not needed and, above all, cannot be moved in any vehicle over about 150,000 km per year.

Using a concrete example, we were able to achieve a weight reduction of over a third, also about one kilogram.

The whole thing with identical load capacity!

And almost as important at the same price level!

Using a concrete example, we were able to achieve a weight reduction of over a third, also about one kilogram.

The whole thing with identical load capacity!

And almost as important at a lower price level!

In addition to the already presented

lightweight ball joints, we can now also apply our lightweight construction

concept to slit bushings with claws. Here, too, weight savings of up to one

third are possible. And in the vast majority of cases even cheaper than with

classic manufacturing methods!

Of course, with identical dimensions

and the same performance!

A marketing gimmick? Magic?

No! Jörn Engineering!

The first projects have already

started!

Be the next to benefit from this

innovation.

Save weight and money!

In this video, Mr. Reinke presents a real novelty.

The lightweight ball joint, patent pending. With the help of a

new technology, ball joints, such as those installed in the chassis of trucks

and tractors, have been made more than a third lighter. All this without

any restrictions in performance and at the same price level as conventional

ball joints.

If you have any questions or are interested, please do

not hesitate to contact us:

lightweight.design@Joern-GmbH.com

Have fun!!