Bicycle

Damping of bicycles with rubber metal components

Damping

with the help of rubber metal components.

Bicycles and their users are exposed to strong mechanical vibrations and shocks. In order to increase the comfort for the rider, to increase the life of the bicycle and to ensure the integrity of the transported goods, these must be reduced.

Jörn offers a variety of solutions for damping cargo bikes with rubber metal components. These can be tailored to your specific application.

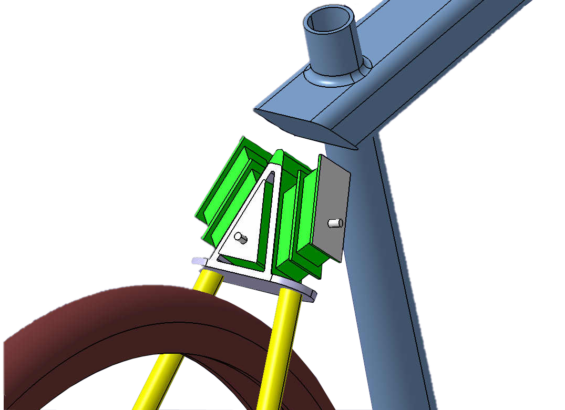

The damping of the rear triangle is realized by a V-shaped rubber-metal mount. This storage can be used for all types of bicycles, e.g. e-bikes or cargo bikes.

It offers many advantages. On the one hand, the system is maintenance-free and comparable in weight to commercially available damper solutions. On the other hand, it offers a gain in comfort for the driver and a reduction in the shock and vibration load of transported goods.

The system can be adapted to different system weights and can be easily integrated into the frame design.

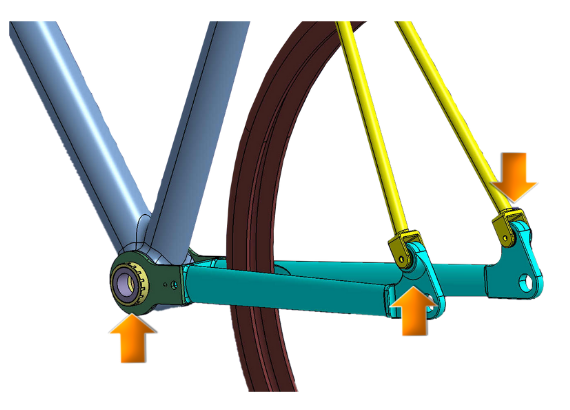

The bearings of the pivot points are usually equipped with plain bearings. The use of rubber-metal

bushings is an improved alternative to this classic solution. The fact that the bushings map the swivel movement in a preloaded rubber body results in the following advantages:

The damping of the rear triangle in combination with the Jörn slit bushings at the pivot points could optimally contribute to a further big step towards maintenance-free operation with a belt drive and hub motor.

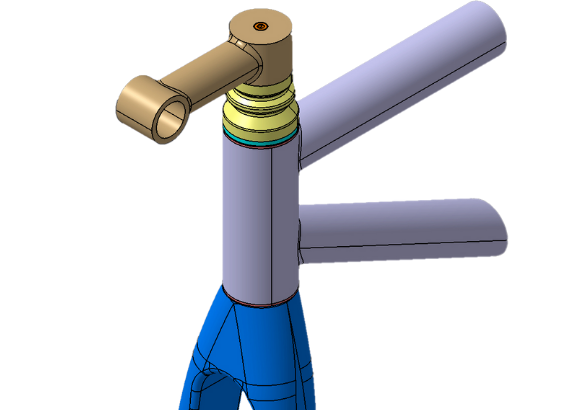

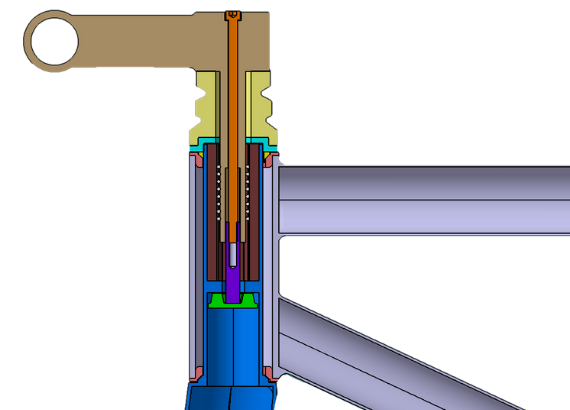

The front suspension of Jörn GmbH reduces shocks and vibrations of the front end. Thus, both driver and

transported goods are spared. Currently, up to 25mm travel is possible.

The damping of the elastomer suspension can be adapted to different load scenarios. The damping elements can be easily integrated into the frame design.

25 mm travel on the handlebars are more than sufficient to noticeably improve comfort in urban areas. That’s all you need. A lot doesn’t always help a lot.

The company Jörn GmbH from Waiblingen presents its rubber metal parts for the suspension of bicycles and cargo bikes. In addition to increasing comfort, the components also contribute to the safety of the wheels. This applies in particular to commercially used cargo bikes, which are subject to the Workplace Ordinance and may therefore only transmit a certain degree of vibrations to the user. In addition to the components, the origin of the components and development is also briefly addressed. Also a look at the first series project in the bicycle sector of the company Jörn, the Kettler Cargoline.

Here the front swingarm is decoupled with the help of 2 Jörn slit bushings and a V-mount.